Build Your Own Joystick Kit - Closed Center

Select options below to build a joystick kit that fits your tractor's setup:

- Function Number: 2-function will control a loader and bucket. 3-function will control a loader, bucket, and grapple.

- Cables Length: Determine where you will install the joystick and the valve. Using a string tape measure, measure the distance from these 2 spots, and select the cable length that most closely matches this distance.

- Pressure Hose Length: Determine where you will install the valve, and where you will be tapping into the tractor's pressure. Using a string tape measure, measure the distance between these two spots, and select the length of hose needed.

- Fitting for Pressure Port: Identify the location you will be tapping into the pressure on the tractor. Where the pressure hose will be attached, what gender, angle, thread size and style will be needed? Select all that apply. For example, "Gender: Male, Angle: 90 Degree, Thread Size: #8, Thread Style: Pipe" will get you a pressure hose that connects to the pressure source on the tractor with a 90 degree, male #8 pipe thread.

- Return Hose Length: Determine where you will install the valve, and where you will be tapping into the tractor's return. Using a string tape measure, measure the distance between these two spots, and select the length of hose needed.

- Fitting for Return Port: Identify the location you will be tapping into the return on the tractor. Where the return hose will be attached, what gender, angle, thread size and style will be needed? Select all that apply. For example, "Gender: Male, Angle: 90 Degree, Thread Size: #8, Thread Style: Pipe" will get you a return hose that connects to the return source on the tractor with a 90 degree, male #8 pipe thread.

- Working Hoses Length: Determine where you will install the valve. With the loader installed on the tractor, use a string tape measure to measure the distance between where the valve will be installed and up to the steel lines on the loader, and select the length of hose needed.

- Fitting for Loader Steel Lines: What gender, angle, thread size and style is needed to connect the working hoses to the steel lines on the loader? For example, selecting "Gender: Female, Angle: Straight, "Thread size #8, Thread Style: JIC will get you working hoses that connect to the loader steel lines with a straight, female #8 JIC thread.

Build your own joystick kit for tractors with closed center hydraulic setup.

Included Items

Items included in 2-function build-your-own kit:

Joystick, cables, cable connection hardware, 2-section hydraulic control closed center valve, 4 Pioneer quick coupler sets which are installed on valve, 4 working hoses from Pioneer couplers to loader steel lines, pressure hose, and return hose (all hoses are 1/2" diameter). Based on options chosen, the pressure, return, and working hoses will have the correct tips for connecting to pressure and return on tractor and steel lines on loader.

Items included in 3-function build-your-own kit:

Joystick with buttons, 2 cables, 1 wiring harness for 3rd function, cable connection hardware, 3-section hydraulic control closed center valve (3rd section is electric), 6 Pioneer quick coupler sets which are installed on valve, 6 working hoses from Pioneer couplers to loader steel lines, pressure hose, and return hose (all hoses are 1/2" diameter). Based on options chosen, the pressure, return, and working hoses will have the correct tips for connecting to pressure and return on tractor and steel lines on loader.

Hydraulics Fundamentals: Items Needed to Control Tractor Add-On Equipment

Every tractor has built-in hydraulics, which means any tractor you’re working with has pressurized oil that can control add-on equipment. The information here covers the fundamentals of adding hydraulic components for controlling a front end loader being put on a cab tractor with a closed center hydraulic setup that has never had a loader before. The same principles apply if adding something else like a snowplow or backhoe to a tractor, as well.

Overview: A tractor with a cab will have a joystick mounted in the cab, with the joystick connected to the valve via cables or a wiring harness, or both. The valve is typically mounted under the cab, but can be installed anywhere on the outside of the tractor. On a closed center tractor, there are two hoses, called the Pressure hose and the Return hose, that connect the hydraulic control valve to the tractor's hydraulics. There are also Working Hoses carrying oil from the control valve to the steel lines on the loader; these hoses are connected to the valve with Pioneer quick couplers. The quick couplers allow the hoses to be disconnected from the valve when the loader is removed from the tractor.

The Joystick: When the joystick is moved, it opens and closes parts of the valve, which then allows pressurized oil to flow in the directions needed to move the loader and bucket: for example, raising the loader arms and tilting the bucket.

The Cables and Wiring Harness: Moving the joystick moves the cables. When the cables move, they are moving sections inside the valve, and these moving sections are directing the oil flow. Pressing the buttons on the 3-function joystick handle communicates with the valve via the wiring harness, which moves valve components through an electrical current.

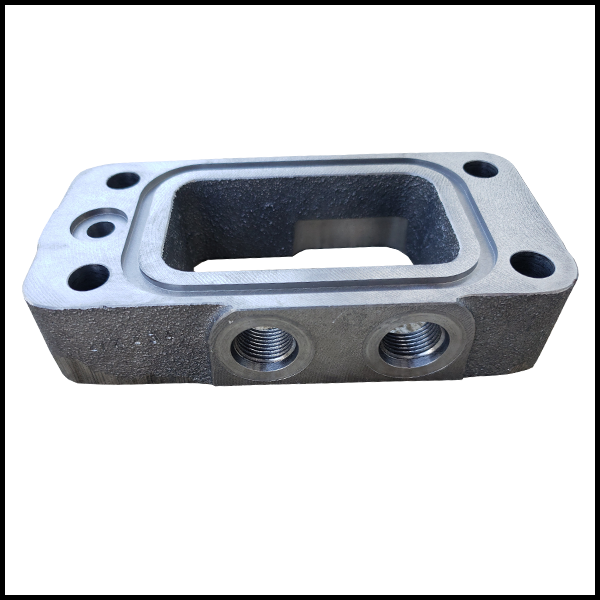

The control valve: The control valve has multiple hoses connected to it via threaded ports built into the valve. On any control valve, there will be “working ports.” These ports are connected to the hoses that carry the oil to the front end loader and bucket, or whatever add-on equipment you’re working with. A closed center hydraulic control valve will also have a pressure and return port. Oil has to be flowing through a control valve in order for it to function. The Pressure Port has a hose connected to the tractor’s pressurized oil and is where the oil flows into the valve. The Return Port is where the oil flows out of the valve, and is connected to the tractor where the oil flows to the tractor’s reservoir, which is a tank of oil stored internally on the tractor.

Hydraulics Fundamentals: How To Tap into Pressure and Return on Closed Center Tractor

A closed center control valve being added to a tractor needs oil flowing into it from the tractor's hydraulics, and oil flowing from it back to the tractor's hydraulics. One hose, the pressure hose, is connected to pressurized oil in the tractor's hydraulic setup and the pressure port on the control valve. The second hose, the return hose, is connected to the return port on the valve and to the return section of the tractor's hydraulic setup.

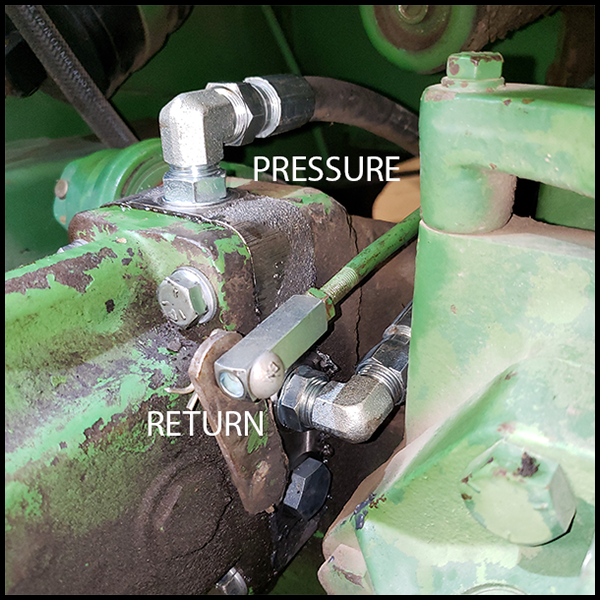

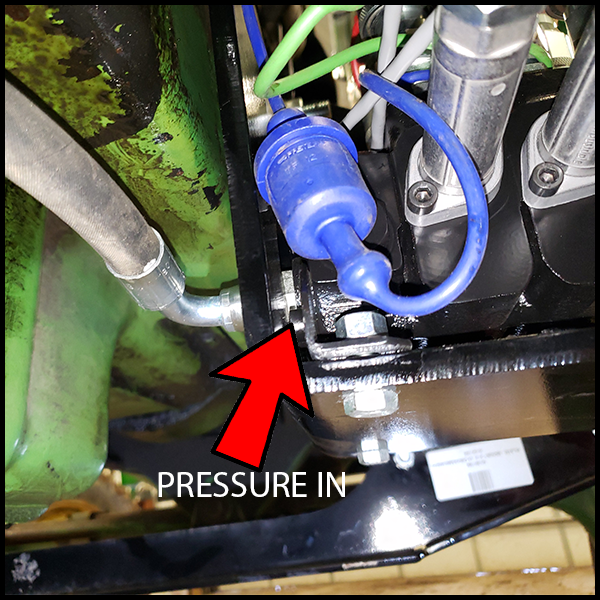

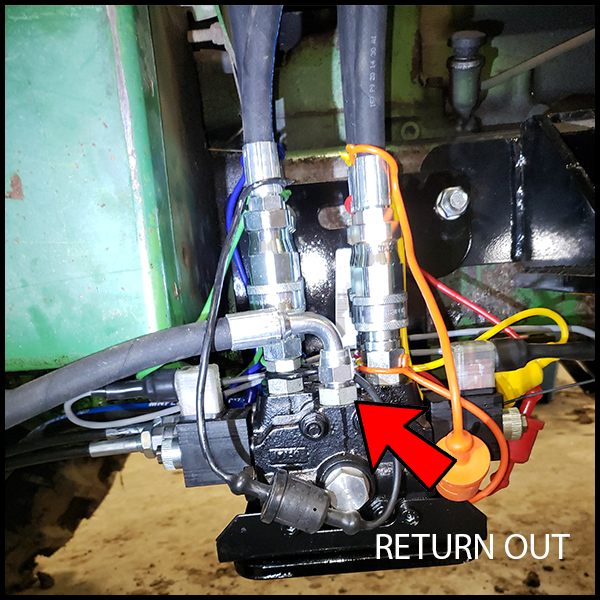

Some closed center tractors - for example, the John Deere 4440 - have a power beyond block option for accessing the pressure and return on the tractor. In this setup, there is one hose connected from the pressure port on the power beyond and running to the pressure port on the valve, and a second hose connected from the return port on the valve and running to the return port on the power beyond block. The pictures below show the power beyond block installed on a John Deere 4440 tractor, and supplying pressure and return to and from the add-on hydraulic control valve:

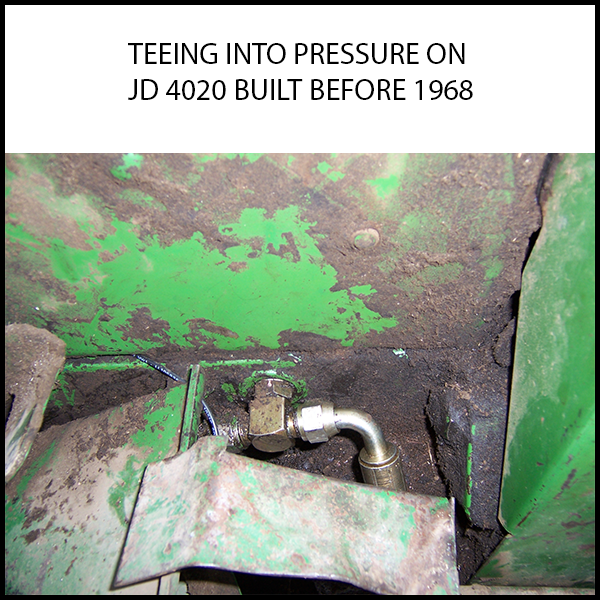

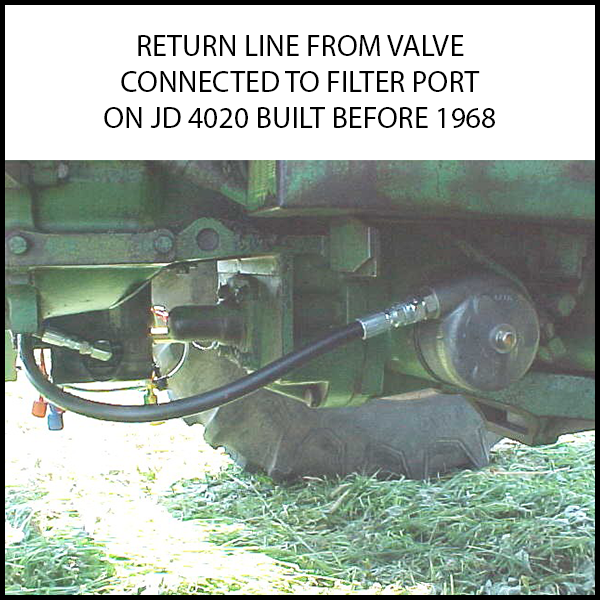

If a power beyond block is not available, the pressure and return on the tractor will need to be tapped into another way. The steps below describe how to tap into the pressure and return on a tractor that does not have a power beyond block available:

- Find the pump. Typically there are 2 lines coming out of the pump, a smaller and a larger line. The smaller of the two lines will be the pressure line. The larger of the two lines will be the return line. (In some situations, there will be two small lines and one larger line. In this situation both of the smaller lines are pressure; one will be running to the steering, and the other will be running to the rear of the tractor - if you follow this line all the way, it will go to the rear remotes or 3 point valve. The pressure line that goes to the rear of the tractor is the line you want to tee into.)

- Tee into the pressure line and run a hose from this tee up to the pressure port on the valve.

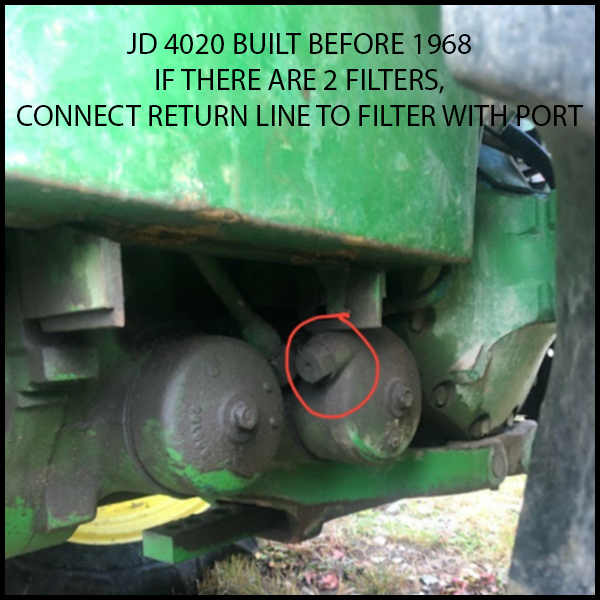

- The hose connected to the return port on the valve should run from the valve’s return port to the filter. The tractor's oil at this location is coming from the tank and running through the filter just before it travels on to the hydraulic pump. Tapping the return oil from the new valve in at this location ensures a short path to the pump, which is ideal.

An example of a tractor with closed center hydraulics that is not designed to receive a power beyond block is the John Deere 4020 tractor built before 1968. The pictures below show how the pressure and return is accessed on this tractor:

Hydraulics Fundamentals: Understanding the Three Types of Tractor Hydraulic Setups - Open Center, Closed Center, and Load Sense

Knowing your tractor’s hydraulic setup is important when adding a hydraulic control valve, or tapping into the hydraulics with a tee or a power beyond block. The three types of hydraulic setups you’ll see most often with tractors is open center, closed center, and load sense. Most compact and utility tractors are set up with open center hydraulics. Many John Deere farm tractors made between the 1970s and the 1990s are set up with closed center hydraulics. Most farm tractors built since the 1990s are set up with load sense hydraulics.

What’s the difference between the hydraulic setups?

- Open Center: A tractor with an open center hydraulics setup will have hydraulic oil that is flowing all the time. The hydraulic pump never stops, even when you aren’t using any of the hydraulics. For example, your tractor could be sitting in the driveway idling and its hydraulic pump would still be running. Any control valve on an open center tractor will have oil constantly flowing in the pressure port and out the return port. When you move your joystick, the spool inside your control valve is directing oil that’s already moving in a different direction. For example, if you move your loader control joystick to raise your loader arms, the hydraulic oil will switch from going out the return hose connected to the valve, to going out the hoses that carry oil to the loader cylinders.

- Closed Center: A tractor with a closed center hydraulics setup will also have a hydraulic pump that is constantly running, but the oil is NOT constantly flowing. If you aren’t using any hydraulics on your tractor, the oil is being pushed into your control valve’s pressure port, but it’s not being let out the return port. The oil’s normal path is being cut off inside the control valve, like pushing a cork in the end of a garden hose. Just like pulling the cork out of the end of the garden hose, with water gushing out, the same is happening when you push your tractor’s joystick. The pressure inside the control valve is suddenly released and the oil gushes into the cylinders - say the raise cylinders on your loader- causing a fast response. This quick responsiveness is nice, because it makes the equipment you're controlling sensitive to the lightest touch. This is the main reason John Deere used the closed center hydraulics setup on their farm tractors for awhile. The drawback, though, is it’s hard on the pump, because the pump is constantly working against built up pressure, which is why closed center hydraulic design was eventually phased out in newer tractors.

- Load Sense: Load Sense hydraulics setup is basically a closed center setup that is easier on the hydraulic pump. The oil isn’t allowed to flow freely through the control valve, thus there is that built up pressure that gives the nice quick response when you activate the hydraulics. But the pump isn’t stressed, because the pump is getting signals either to go into low gear or high gear based on your hydraulic needs. If you’re not using any hydraulics, the pump receives a signal to pump lightly - enough to build up pressure but not enough to stress the pump. When you activate your hydraulics - turning the steering wheel or pulling a control lever - the pump receives a signal to kick into full gear, providing enough pressure to run the hydraulics. There is an extra port on a load sense control valve, which attaches to a hose that is smaller than the pressure and return hoses. This smaller hose is carrying a little bit of “signal” oil - as soon as you activate your hydraulics, the signal oil flows into the load sense port, signaling the pump to kick in with full power.