Complete Joystick Kit for AGCO Tractors

Complete Joystick Kit for AGCO Tractors.

If you have questions or need a joystick kit for a tractor not listed here, call: 605-951-0167.

Complete Joystick Kit for AGCO Farm Tractors

Select the dropdown options to select your AGCO tractor model and number of functions needed.

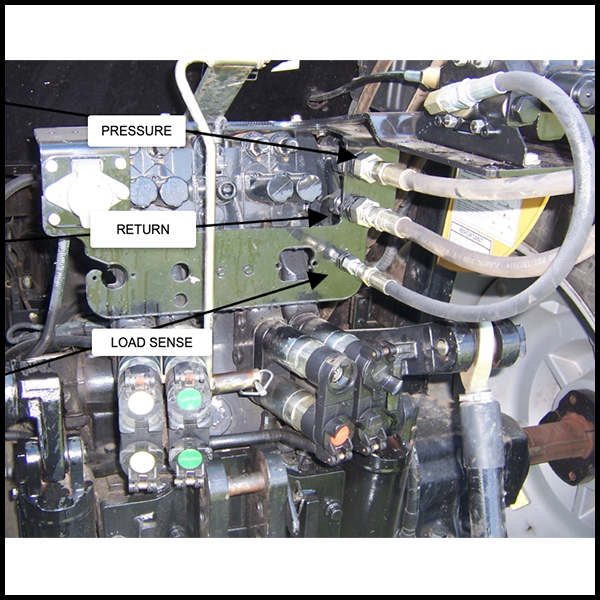

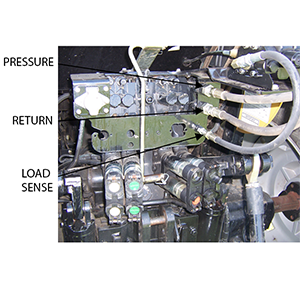

The images below show where the joystick, valve, and couplers are installed on the AGCO tractor models LT75 (LOAD SENSE) AND LT90 (LOAD SENSE). Also shown is how the pressure, return, and load sense ports are accessed on these tractors.

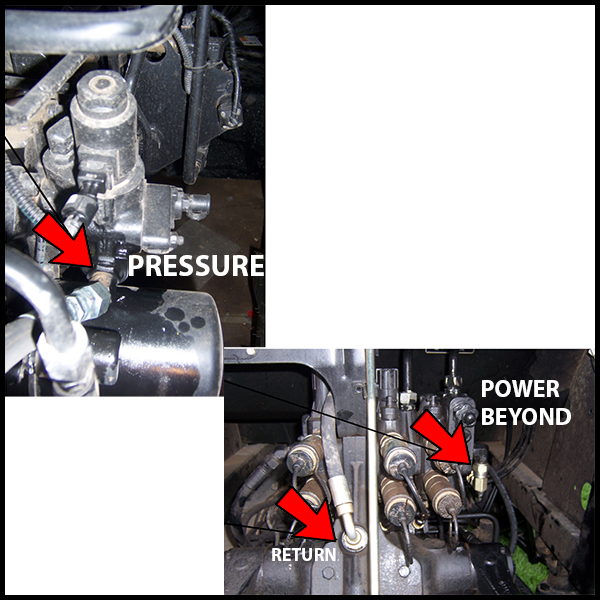

The images below show where the joystick, valve, and couplers are installed on the AGCO tractor models LT75 (OPEN CENTER) AND LT90 (OPEN CENTER), as well as the CAT CHALLENGER MT445B (OPEN CENTER), MT455B (OPEN CENTER), and MT465B (OPEN CENTER) (these pictures show the joystick kit is installed on the equivalent Massey Ferguson tractor). Also shown is how the pressure, return, and power beyond ports are accessed on these tractors.

The images below show where the joystick, valve, and couplers are installed on the AGCO tractor models RT100A, RT120A, RT135, and RT150. Also shown is how the pressure, return, and load sense is accessed on these tractors.

Key Features of Complete Joystick Kit:

- High quality components.

- Tractor-specific mounting brackets for joystick, valve, and couplers.

- Tractor-specific items needed to tap into pressure, return, and (if applicable) load sense on tractor.

- All needed hydraulic hoses are included in kit: hoses supplying pressure, return, and (if applicable) load sense to valve, and hoses from valve to loader lines. The lengths of the hoses are cut to match the tractor dimensions and where the valve is located.

- All needed hydraulic fittings and Pioneer couplers are included in kit.

- Written installation instructions are shipped with kit.

Complete Joystick Kit Options:

- Tractor model - each complete joystick kit is designed specifically for the tractor it is going on.

- 2-Function or 3-Function - A 2-function kit controls the loader and bucket. A 3-function kit controls the loader, bucket, and grapple.

2-Function versus 3-Function Joystick Kit:

The 2-function joystick kit is for a tractor with a front end loader that does NOT have a grapple. This kit has two cables that control the raise and lower loader functions and the tilt and retract bucket functions.

The 3-function joystick kit is for a tractor with a front end loader that DOES have a grapple. This kit has two cables that control raise and lower of the loader arms and tilt and retract for the bucket. It also has an electric third function for controlling the grapple. Buttons are built into the joystick handle, and are used to open and close the grapple. A wiring harness running from the joystick to the electric 3rd section on the valve control the grapple.

If you don't have a grapple at the time you're purchasing a joystick kit, but might add a grapple later on, it is a good idea to get the 3-function kit upfront. The features of the 3-function kit won't cause any problems with the 2-function functionality, and then the buttons and 3rd section are there and ready to use when you add a grapple later. The wiring harness and extra hoses and couplers could be set aside to be installed when the grapple was installed later. On the other hand, we also carry a 3-function conversion kit, which allows you to purchase the items needed to turn our 2-function joystick kit into a 3-function kit. The drawback to this is adding the 3rd function section to the valve, which doesn't necessarily require a hydraulic technician but is more difficult than if the valve is already purchased with the 3rd section included.

Items included in the joystick kit:

The 2-function joystick kit includes the following:

Joystick without buttons, 2 cables, 2-section hydraulic control valve, cable connection hardware, pressure return and (if applicable) load sense hoses, hoses from valve to loader steel lines, 4 Pioneer quick coupler sets, and a way to tap into the pressure return and (if applicable) load sense on the tractor. Tractor-specific brackets for mounting the joystick and valve are included, as well as all needed fittings and installation hardware. Written installation instructions with pictures are shipped with the kit.

The 3-function joystick kit includes the following:

Joystick with buttons, 2 cables, wiring harness, 3-section hydraulic control valve (2 manual sections, 1 electric section), cable connection hardware, pressure return and (if applicable) load sense hoses, hoses from valve to loader steel lines, 6 Pioneer quick couplers sets, and a way to access the pressure return and (if applicable) load sense on the tractor. Brackets designed for the specific tractor model are included for installing the joystick and control valve. All needed hydraulic fittings and and installation hardware are included as well. Written installation instructions with pictures are shipped with the kit.

This is called a complete joystick kit because it includes everything you need for controlling a front end loader on a tractor. Typically this kit is being used in a situation where a loader is being put on a farm tractor that has never had a joystick kit before, or a setup where there is an existing FEL on a tractor but it's being controlled by the rear remotes, and the user prefers to upgrade to a joystick to control the loader.

The Joystick

The joystick included in the kit is high-quality (built in Italy). However, like any high-use tractor parts, depending on hours of use, several of the internal items do tend to wear out over time, mainly the pivot section of the joystick. We carry replacement parts for the internal components of this joystick. To give an idea on timeframe for replacing parts on the joystick: for a joystick that's being used daily for multiple hours per day, the pivot parts typically need to be replaced every 1-2 years. For a joystick being used just here and there, typically parts never need to be replaced on it. The joystick included in the 2-function kit is mechanical, attached to the two cables controlling the loader arms and bucket. The joystick included in the 3-function kit is a combination of mechanical and electric; it is attached to the two cables controlling the loader arms and bucket, and it also has two buttons (switches) built into the grip. The electric buttons are typically being used to control a grapple; they are all-on or all-off (no feathering). If the third function is being used for something that needs a slower hydraulic flow, like a bale squeeze, a restrictor can be added to the third oil line. The pictures below show the current joystick used in these kits. Note: the pictures of the installed kit may be an older-version joystick, as some of these pictures were taken by the R&D department at the time the joystick was developed, and the specific joystick used in the kit may have changed since then.

The Cables

The 2-function joystick kit is designed to mechanically control the loader and bucket via cables. The 3-function kit also controls the loader and bucket via cables, with the electric 3rd function controlling the grapple via buttons and a wiring harness. Because both kits are physically controlling the loader and bucket, two cables are included in both the 2-function and 3-function kits. The length of the cables varies depending on the specific kit, as the distance between the joystick and the control valve can be different depending on the tractor. The cables are built in Italy and are high-quality; however, like the joystick, depending on hours of use, they can wear out over time. We carry replacement cables which can be purchased as needed. The picture below shows a cable:

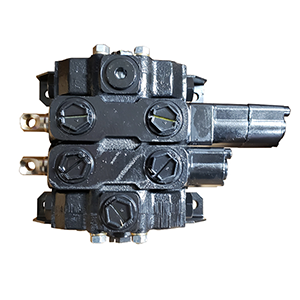

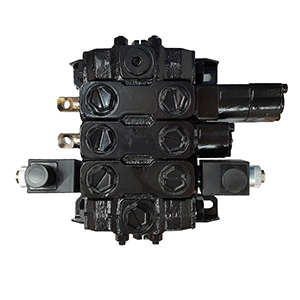

The Valve

The most important component in the kit is the hydraulic control valve. This is the part of the kit that is directing the flow of oil which controls the loader, bucket, and grapple. Each tractor is built with a certain type of hydraulic setup, and the way the valve is built must match the tractor's hydraulic setup (open center, closed center, or load sense). Most farm tractors built since 1990 have load sense hydraulics, which means the hydraulic pump senses when hydraulic pressure is needed and provides high pressure when activated. Some John Deere farm tractors built before the 1990's have closed center hydraulics, which means the hydraulic pump is always running but the oil can't return to the tank until a hydraulic function is activated, providing high hydraulic pressure at all times. A few farm tractors of various makes have open center hydraulics, which means the hydraulic pump is always running and hydraulic oil is constantly flowing to the tank. The control valve included in each kit is selected to match the hydraulic setup of that tractor - for example, the joystick kit for the John Deere 4440 has a valve designed to work with a closed center hydraulic setup, whereas the kit designed for the John Deere 6400 has a valve designed for a load sense hydraulic setup.

The valve in this kit is extremely high quality, built in Italy by Bondioli, a company that manufactures high-end OEM hydraulic components for a variety of machinery. In our experience, this valve rarely needs to be rebuilt and rarely has any components that go bad, regardless of hours of use.

The 2-function valve is designed as a completely manual valve, meaning it has no electrical components, and the spools are moved via cables. The 3-function valve is designed as partly manual, partly electric: the two spools controlling the loader and bucket are moved via cables, and the third spool controlling the grapple is moved by solenoids connected to a wiring harness which runs up to the buttons on the joystick handle.

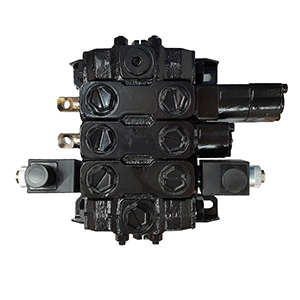

The pictures below show the 2-function and 3-funtion control valves used in this kit:

The Brackets

Each kit has tractor-specific brackets for mounting the joystick, valve, and Pioneer quick couplers.

The Instructions

Each joystick kits is shipped with written installation instructions, which includes a schematic, detailed step-by-step instructions, and pictures. Some of the kits also have installation videos, showing in detail each of the installed component on the tractor it is designed for.

| Component | Picture |

|---|---|

| 2-Function Joystick |  |

| 3-Function Joystick |  |

| Cables |  |

| 2-Function Valve |  |

| 3-Function Valve |  |

What makes the joystick kit tractor-specific?

We offer complete joystick kits for a wide variety of farm tractor makes and models, including John Deere, New Holland, Case, Case-IH, Massey Ferguson, McCormick, AgCo, International, etc. As listed above, each kit contains the same type of items, for example a joystick, cables, control valve, brackets, hoses, etc., but some of these items are designed specifically for the tractor. For example, the way that the joystick and valve mounts is going to be unique for most tractor model series, so the brackets for installing the joystick and valve is specifically designed to match the tractor the kit is going on. Since the way the pressure, return, and load sense is accessed also varies by tractor models, the hoses from the tractor to the valve have fittings and lengths that vary by tractor. The distance from the valve to the loader steel lines will vary as well, so these hose lengths will be different between tractors also. The cable length will vary depending on where the valve is installed, also. The control valve hydraulic setup in each kit matches the tractor's setup: open center, closed center, or load sense.

Installing the components:

While the specific installation steps will vary depending on the tractor model, these steps give an overview of typical installation tasks. It typically takes about 8 man hours to install the complete joystick kit from start to finish. (For reference, an experienced mechanic can usually install a kit in about 4-5 hours. Most of our kits are installed by the farmer that owns the tractor and is working in his own farm shop; installation typically takes about 8 hours in this case.)

Joystick and cables: The joystick bracket is typically being installed either on the front-right post of the cab, beside the seat, or on the side of the cab wall.

The cables and wiring harness go down through the floor of the cab to the control valve. In most tractors, a hole needs to be drilled in the floor for the cables. In some cases there already is a hole there for this purpose. This video shows how to attach the cables to the joystick base:

Hydraulic control valve: Most of the kits have the control valve installed under the front-right section of the cab, and if possible existing bolt holes are used. In some cases, though, there is not enough room to install the valve in this spot, so in some kits the valve is installed on the rear of the tractor. In this case the cables do still go down through the floor, but then are bent back to go to the valve on the rear, typically right under the rear cab window.

Pioneer couplers: In most kits, the Pioneer couplers are attached to a bracket that is installed on the loader mounts. With this setup, there is a set of hoses running from the valve up to the couplers, and then another set of hoses running from the couplers up to the loader steel lines. In several kits, the Pioneer couplers are installed directly on the control valve, and the hoses run all the way from the control valve up to the loader steel lines. Hose clamps and hose wrap is included to keep these hoses tidy.

Pressure, Return, and Load Sense: Most of the kits include a power beyond block, which taps into the pressure, return, and (if applicable) load sense of the tractor, supplying the oil flow to and from the midmount valve. For the tractors that have pressure, return, and load sense ports built in to the tractor, the correct hoses and fittings are provided for connecting to these ports. In tractors that require teeing in, the correct items are included. This part of the kit varies the most between tractor models. The installation instructions that ship with the kit include written instructions and pictures of how this is installed.

Hydraulic fittings: All needed hydraulic fittings are included in the loader control joystick kits. Since the kits are tractor-specific and are being used with a variety of loaders, the one time you may need to modify the kit slightly is adding hydraulic adapters between the tips of the hoses in the kit where they connect to your loader's steel lines. The tips of our hoses where they connect to the loader lines are typically JIC.

Cable connection hardware: The cable connection hardware assembly is the same in each kit. This video shows how to assemble this hardware:

Wiring harness: The wiring harness plugs into a pigtail on the joystick, and is run with the cables down through a hole in the floor of the cab to the control valve.

Warranty information:

All components in the joystick kit are covered by a 1-year warranty.